All about the RATIONAL SCC-101-E

FEATURES

- Outstanding food quality at all times

- Easy to operate even for untrained staff

- Minimum running costs

- No checking or monitoring

- Cook different foods at the same time

- Automatic cleaning and descaling

- Rear-ventilated triple-glazed cooking cabinet door, two hinged inside panes (for easy cleaning) with a

special heat-reflecting coating - LED cooking cabinet and rack lighting – energy-saving, durable and low-maintenance

- Optical rack signalling function

- Core temperature probe using 6 measuring points with automatic error correction. Positioning aid for core

temperature probe included - Climate management – humidity measured, set and regulated to one percent accuracy. Actual humidity in

the cooking cabinet can be set and read on the control panel in Combi-Steamer modes - Individual Programming of at least 1200 cooking programs with up to 12 steps

- Humidification variable in 3 stages from 86°F–500°F (30°C–260°C) in hot air or combination

- Integrated Ethernetsocket to connect to a cloud based system for administration of cooking processes,

management of HACCP and service data and remote control - High-performance, fresh-steam generator with automatic descaling

- Dynamic air circulation in cooking cabinet with reversing wheel fan with 5 fan speeds, programmable

- Integral, maintenance-free grease extraction system with no additional grease filter

- Operation without a water softener and without additional descaling

- Separate solenoid valves for normal and soft water

- Cool-down function for fast cabinet fan cooling

- Automatic adaptation to the installation location (height, climate, etc.)

- Removable, swivelling hinging racks (distance between rails 2 5/8″ / 68 mm)

- Material inside and out 304 (DIN 1.4301) stainless steel

- Hand shower with automatic retracting system

- Fixed waste water connection conforming to SVGW requirements were permitted

- Demand-related energy supply

- Lengthwise loading for 12”x20” or 1/1, 1/2, 2/3, 1/3, 2/8 GN accessories

- 5 programmable proofing stages

- Automatic, pre-selected starting time with adjustable date and time

- Uses the LED lighting to signal the end of the preheating phase or the process

Description

- Cooking appliance for automatically cooking (Automatic mode) meat, poultry, fish, side dishes/vegetables, egg dishes/desserts, bakery products and for automatic finishing®. With an intelligent system for optimising

mixed loads in production and in à la carte service as well as a fully automatic cleaning and care system. - Hot-air steamer (combi-steamer mode) conforming to DIN 18866 for most of the cooking methods used in

commercial kitchens for the optional use of steam and hot-air, individually, in succession or in combination.

Working safety

- Detergent and Care tabs (solid detergents) for optimum working safety

- HACCP data output and software update via the integrated Ethernet and USB port

- Safety temperature limiter for steam generator and hot-air heating

- VDE approved for unsupervised operation

- Maximum rack height 1.60 m for use on an original base cabinet

- Integral fan impeller brake

- Door handle with right/left and slam function

Operation

- Remote control function for appliance using software and mobile app

- iCC-Cockpit – graphically supported overview of the current cooking chamber climate, the expected progress of the cooking process, review and forecast as well as options at the end of cooking

- iCC Messenger – informs on current and automatic adjustments to the cooking process

- iCC Monitor – Overview of all automatic adjustments to the cooking process

- 9 self-configurable, user-specific operating display (images, text, etc.)

- Record mode – Determination of the ideal cooking path for calibrated products using the core temperature probe for subsequent use without a core temperature probe, with automatic consideration of load quantity

- Self-learning operation, automatically adapts to actual usage

- 8.5″ TFT color monitor and touch screen with self-explanatory symbols for ease of operation

- Control second unit from the main unit (units must be connected via ethernet or network)

- Application and user manuals can be called up on the unit display for the current actions

Cleaning, care and operational safety

- Automatic cleaning and care system for cooking cabinet and steam generator works regardless of the water pressure supplied

- 7 cleaning stages for unsupervised cleaning and care – even overnight

- Automatic cleaning and descaling of the steam generator

- Automatic cleaning prompts indicating the cleaning stage and volume of chemicals in relation to the level of soiling

- Soiling and care status are displayed on the monitor

- Diagnostic system with automatic service notices displayed

- Self-Test function for actively checking unit’s functions

More information

iCookingControl®

- Top-quality cooking results with no monitoring

- Easy to operate, even for temporary staff

- Reduces raw materials use by up to 10% than units without HiDensityControl®

- Healthy food preparation using up to 95% less grease

Your wishes will be granted precisely. Without you having to do a thing.

iCookingControl® also uses sensors to detect the size and condition of your products as well as the load sizes, and automatically adjusts its path to your desired results accordingly. It takes any required decisions on its own, setting temperature, cooking cabinet climate and cooking times automatically.

The display informs you of every adjustment. You’ll know exactly what’s going on, and will always have an eye on everything.

Simplicity through cooking intelligence. This is one assistant cook you can always rely on.

iCookingControl® learns your preferences and cooking habits, and adjusts its controls to meet your needs. You won’t need to do any more checking or monitoring, and you can rely on the fact that everything will come out exactly the way you want it.

Progress on the display. Left to right.

- You specify your desired result. The SelfCookingCenter® implements your ideas reliably.

- With the iCC® Cockpit, you will always know exactly what your cooking system is doing.

- The iCC® Monitor shows you which settings are being applied.

HiDensityControl®

- Exceptional uniformity from the first rack to the last

- Crisp crusts and crunchy breadings

- No drying out, even of delicate foods

- Traditional grill marks even with large quantities

- Short preheating periods, and thus minimum energy consumption

Precision means top quality. Automatic cooking cabinet climate adjustment.

Highly sensitive sensors detect and identify the current conditions inside the cooking cabinet every second, so that energy levels can be optimised in accordance with the needs of the food. And it all happens precisely and efficiently.

The results: Consistently high food quality and minimal resource consumption, from the first rack to the last.

Fresh steam generator. Hygienic steam at the push of a button, any time.

Precise steam temperatures and maximum steam saturation—even with full loads, and even at temperatures as low as 30 °C—guarantee top-quality, healthy, nutritious results with no need for an elaborate and expensive water softening system.

Cooking cabinet management. Heat, air, and moisture.

Intelligent climate management: The humidity sensor also accounts for the food’s natural moisture levels, and allows cooking cabinet climate parameters to be set and adjusted to one percent precision. The results? Browned, juicy roasts and light crumb.

Dynamic air circulation: The high-performance fan impeller adjusts its speed and direction of rotation depending on product types, quantities and cooking states. This ensures optimum air distribution for uniform results.

Active dehumidification: Innovative vacuum technology dehumidifies the cooking cabinet quickly and efficiently, providing crisp crusts, crunchy breading and attractive grill marks with delicious roasted flavours.

Precision means top quality. Automatic cooking cabinet climate adjustment.

Fresh steam generator. Hygienic steam at the push of a button, any time.

LevelControl

- Maximum flexibility

- Consistently high food quality

- Energy savings of up to 70% compared to conventional cooking technology without combi-steamer

- Ease of operations with no monitoring

Intelligent mixed loading. iLevelControl adjusts automatically.

The display on your SelfCookingCenter® will show you which dishes you can cook together. You specify what you want to prepare and iLevelControl will monitor each rack individually. Depending on load sizes and on how often the door is open for how long, iLevelControl will intelligently adjust cooking times and even notify you as it’s doing so. That way, you’ll always have an eye on the proceedings.

When a rack is finished cooking, iLevelControl will notify you with a corresponding message on the display. If you like, the system will even use the lighting system to show you which rack needs to be loaded or unloaded. This almost completely eliminates the possibility of operator error. Your food will come out perfectly every time, just the way you want it.

Efficient CareControl

- No additional expenses related to descaling or water softening systems

- Clean Hygiene Guarantee ensures that your unit is always clean and well maintained

- Minimal operating costs and workload

- Usage of solid cleaning agents provides additional work safety

Cleaning and descaling. With the SelfCookingCenter®, they’re automatic.

If you choose, you can also save a cleaning schedule that fits your working hours. The SelfCookingCenter® will message you automatically at the scheduled times, and will make sure that your unit remains hygienically clean and well-maintained.

Expensive, high-maintenance water softening systems are no longer necessary. The new Efficient CareControl needs around 30% less resources than the previous model*, making it significantly less expensive than a thorough manual cleaning—and thanks to its use of cleaning tabs, it’s particularly safe as well.

Technical details & equipment.

LED lighting with rack signaling.

LED lighting with rack signaling.

Our new and innovative LED lighting ensures optimum illumination of both the cooking cabinet and each individual rack—top to bottom, back to front. The neutral lighting helps you see products’ natural browning. Energy-efficient, durable and low-maintenance. The new tray lighting option makes using iLevelControl even easier: A blinking light signals which tray needs to be loaded or unloaded.

Triple-glazed cooking cabinet door.

Triple-glazed cooking cabinet door.

The triple glazing has a state-of-the-art heat-reflective coating to ensure minimal heat losses, which saves you another 10% in energy costs. All three panels can be cleaned, so you’ll have a clear view of things for years to come.

Integrated hand shower with automatic retraction system.

Integrated hand shower with automatic retraction system.

An infinitely-variable jet and ergonomic handling facilitate rough cleaning work, deglazing or adding water. The integral automatic retraction system and automatic water shut-off mechanism offer optimum safety and hygiene conforming to EN 1717 and SVGW standards (Swiss Association for the Gas and Water Industry).

Energy consumption display.

Energy consumption display.

You’ll always know how much energy an individual cooking process requires, or how much energy your appliance is consuming per day. Energy consumption data can be viewed on the display, and is also available for download.

300°C maximum cooking cabinet temperature.

300°C maximum cooking cabinet temperature.

The SelfCookingCenter® particularly robust construction allows even continuous operation at temperatures of up to 300°C, so special cooking methods like grilling or searing are equally possible with large quantities of food.

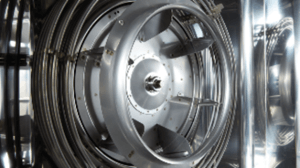

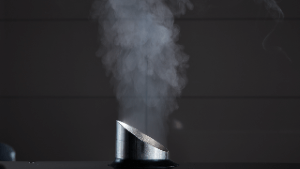

Steam generator.

If you’re aiming for top quality steaming results, our steam generator is indispensable. The 100% fresh and hygienic steam guarantees maximum steam saturation even at low temperatures, for example when poaching.

The steam generator is automatically descaled as part of the cleaning process, making expensive water softening measures superfluous.

Centrifugal grease trap system.

Centrifugal grease trap system.

Cooking cabinet air stays clean at all times, with no need to replace or clean grease filters. Pure taste enjoyment.

Lengthwise loading.

Lengthwise loading.

Loading lengthwise means the door need not be opened as far, which helps reduce energy losses significantly, even if you’re opening and closing the door frequently as part of à la carte operations. The small opening radius requires less space as well. 1/3 GN and 2/3 GN containers can also be used for smaller quantities.

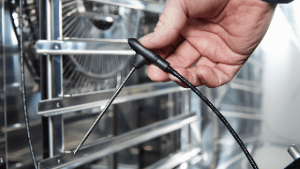

Positioning aid.

Positioning aid.

Our positioning aid makes it easier to position the core temperature probe correctly in liquid, soft or very small products.

Intelligent 6-point sensor.

Intelligent 6-point sensor.

Even if the core temperature probe is not inserted correctly, the sensor can still reliably detect the coldest point within the product, so all products always come out cooked to perfection.

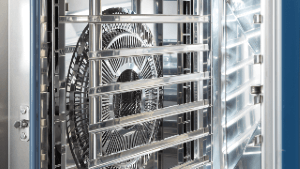

Dynamic air circulation.

Dynamic air circulation.

Thanks to special cooking cabinet geometry and a powerful fan impeller that changes rotational speed and direction based on specific product requirements, heat is always distributed perfectly throughout the cooking cabinet. This ensures excellent food quality even with full loads. The integrated fan wheel brake reacts promptly when the door is opened, so that the fan impeller comes to a standstill quickly for even more safety and security.

ClimaPlus Control®.

ClimaPlus Control®.

Sensors measure humidity inside the cooking cabinet precisely and adjust it to the exact percentage, depending on settings. If necessary, the system will extract excess moisture or use the steam generator to supply additional moisture.

Door drip pan.

Door drip pan.

The integrated, self-draining door drip pan benefits work safety and hygiene, by ensuring that no water drips onto the floor.

Cooking cabinet seal.

Cooking cabinet seal.

The new plug-in door seal has a far longer service life than the previous model. It can withstand temperatures even as high as 300°C. Replacing the seal requires no tools and can be done without the aid of a technician.

Specifications

Dimension: W847 x D776 x H1042mm

Electrical: 380V – 415V / 50Hz / 18600W

Fuse: 3 x 32A

Hot air output: 18000W

Steam output: 18000W

Water inlet: R 3/4″

Water outlet: DN 50

Water pressure: 150–600 kPa or 0,15–0,6 Mpa

Capacity tray size: 10 x GN1/1

No of meals per day: 80 – 150

Weight: 135Kg

Warranty: 2 Years (by Rational)

Made in: Germany

Document Downloads

Product sheet

Operation Manual

Installation Manual

Product video: